Lab Space

I have research space at the University of Alberta for automated inspection systems.

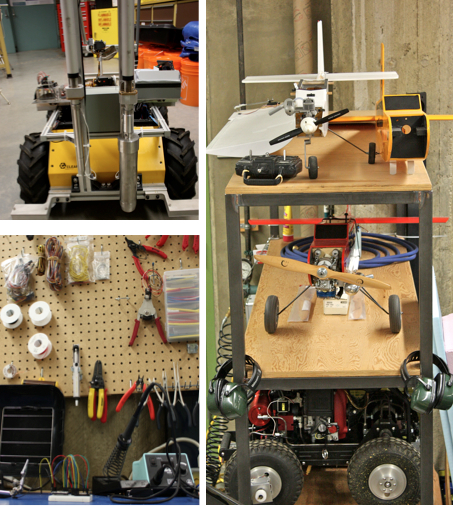

Our group designs, develops and characterizes demonstration prototype field robotic systems for industrial and environmental inspection. including: non contact sensing; contact sensing (such as vibration); sampling of liquids and soils; and cutting, manipulation and retrieval of objects. Systems deployed to date include a patented amphibious rover capable of locomotion over extreme terrain, rotorcraft drones able to collect vegetation and liquid samples, and drones able to do aerial manipulation tasks such as opening a door, along with a range of automatically operated payloads. We also conduct systems engineering analysis to determine when automation is appropriate to improve safety, reliability, and cost-effectiveness.

Room 4-28, Mechanical Engineering Building

Our research group has dedicated 80 m2 laboratory space with 3 m ceilings and high floor loading capability as a work & testing area for machinery diagnostics projects, embedded systems development, and robotics and UAV projects for remote asset monitoring and industrial environmental monitoring.

Equipment includes an Unholtz-Dickie Model 20 shaker table, an experimental modal analysis system, and a four-bar linkage driven by a VFD-controlled 1-hp AC motor through a Spectraquest gearbox suitable for periodic loading studies and fatigue testing. Data acquisition instrumentation includes two 16 channel Bruel & Kjaer vibration monitoring systems, twelve triaxial B&K accelerometers, Labjack computer 4 interface with Toughbook computer. The vibration monitoring system is packaged in a Pelican case and is completely portable as well as fairly weatherproof. There is also a modal analysis hammer.

A Robot C5 robotic manipulator is being used for characterization of anomalous motions for fault detection in nonlinear systems. There is a two-degree-of-freedom gantry system to emulate indoor motions, and a flume for soil terra mechanics studies. This custom testbed is used to characterize wheel-soil interactions for terramechanic locomotion studies. This system can also be used to evaluate aerial manipulation contact task performance. Field robotic systems include a modified hydraulic-drive Quadrover mobile robot, a heavily modified Clearwater Husky mobile robot with payloads for soil characterization, including an active trundle wheel with a 6 degree-of-freedom force-torque sensor. Other payload include remotely operated soil samplers that can be deployed several metres into soft soil, and a vane shear viscometer. A DJI s1000+ octocopter is used for UAV-based inspection and remote condition monitoring, with payloads such as MEMS vibration sensors, infrared cameras, an A-scan ultrasonic thickness transducer, and sampling tools. Several smaller quadcopters are also available.

A number of wireless embedded sensor systems allow biaxial strain measurement at >150 Hz (very useful for wireless shaft torque measurement), resolvers, differential GPS location (there are other IMUs as well), thermistors, etc.

There are four workstations for embedded systems prototyping, a 3D printer, and an electronics table for sensor fabrication and data acquisition system testing.